HVAC is responsible for more than 30% of all electricity consumed in industrial and commercial sectors, with the motors that drive compressors, pumps and fans accounting for more than 98% of that energy. Controlling the HAVC system with different sensors can have a huge effect on the systems.

For this reason with a low investment for the measurement and control of parameters such as Tempreture, Humidity, pressure,… there can be a huge effect on the reduction of cost.

Sample of our experience in HAVC industry with our sensors and systems are as follows:

• Air conditioning,

Heating ,

Air filtration,

Ventilation,

Calculation of outdoor air exchange, Evaluating the frequency of renewal of air, Airflow Duct control,

• Actuators (Ventilation Rate),

Calculation of the percentages of outside air admission (% Outside Air),

Supervision of climate in electrical cupboard

• Air Sterilization by UVC lamps

• Differential pressure smoking rooms

• Air Filter quality performance evaluation

• Evaluation of IAQ (CO2) as reference ASHRAE 62.1- 2004 and BMI in public centers for air exchange: Museums, Gym, Auditorium, Cinema, Sick building analysis, Sick Building Syndrome

• Lighting Control of emergency exits, Automatic Window regulation

• Air compressed pipeline to avoid wetness/musk/frozen risk and to manage dryer (Dew Point)

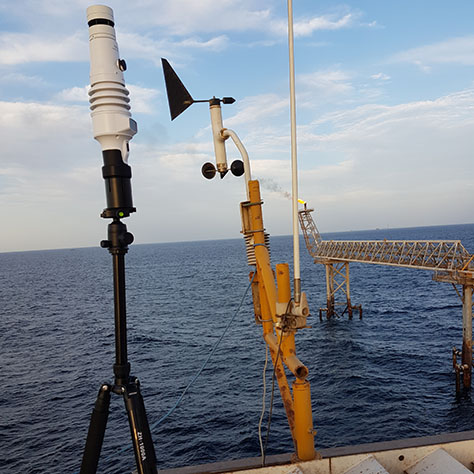

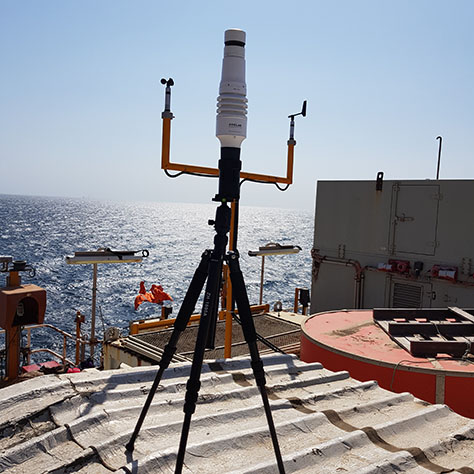

• Outdoor Air Monitoring connected to the building Ethernet/MODBUS network

• Absolute Humidity sensor used to control a dehumidifier (British Standard BS 1339)

• Freezing chamber, Refrigeration,