CEMTEC® for cement plants

Reliable and permanent O2 and COe measurement in high temperatures

CEMTEC®

PRODUCT INFORMATION

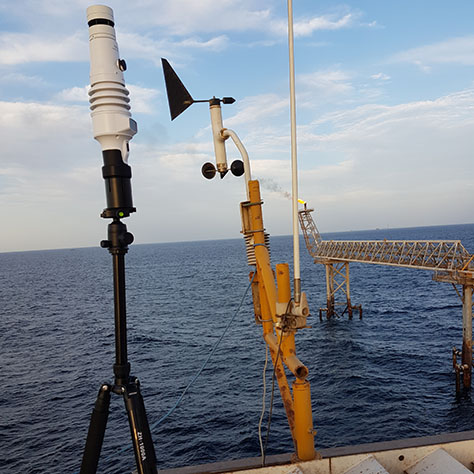

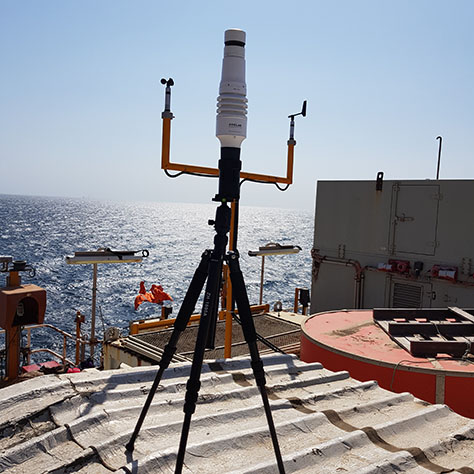

CEMTEC was developed for continuous analysis of flue gas in rotary kilns and other extremely dusty high temperature processes such as cement plants, with the goal of increasing product quality with reduced fuel useage while simultaneously reducing harmful emissions. Particularly in view of the increasing usage of alternative fuels in rotary kilns and large combustion chambers, the on-site gas analysis has become ever more important

Process temperatures up to 1400°C, dust concentrations of up to 2000g/m³, high mechanical stress due to falling material and ambient temperatures up to 55°C make extremely high demands on any technology in use. With its exclusive technical abilities, CEMTEC provides an optimal solution for permanent measurement under challenging conditions as found in kiln inlet chambers of cement plants and large combustion chambers.

The CEMTEC is a self cleaning probe which enables permanent measurement.

95% availibility of measurement is reached with the CEMTEC

A selection of CEMTEC installations can be found here.

FEATURES

- Automated self cleaning

- Swivel drive (prevents fixation of the probe in the process)

- Mechanical cleaning of the sampling probe (no interruption process gas measurment)

- Emergency retraction if disruption to energy, water and air supply

- Continuous monitoring of all system parameters

- Optional InSitu analysis

- Optional air / air heat exchanger

- High quality workmanship

ADVANTAGES

- Continuous operation - 95% availability of measurement

- Long service life combined with high reliability

- Reduced downtime and operating costs due to lower maintenance

- Consistently high product quality through optimised combustion temperature

- Reducing the environmental impact by saving fuel

- Fast response time due to InSitu analysis

HOW IT FUNCTIONS

The CEMTEC gas analyzer consists of a water-cooled gas sampling probe, which is mounted on a pneumatic propulsion device and travels in and out of the combustion process. The process gas is sucked into the filter unit through the tip of the cooling protection tube, and then into the centrally positioned measuring chamber. In addition to the ENSITU sensors for the instantaneous oxygen and COe analysis, a heated gas sampling tube is located in the measuring chamber. The extractive analyzer is supplied with flue gas of approx. 60 l/h through this tube for measurement of e.g. SO2, NOx or CO2.

Thanks to the mechanical cleaning, the continuous extraction and analysis of process gas is possible over a long period of time. The dust filter with an impact plate at its tip is coaxially mounted within the cooling protection tube and moves in programmable intervals out of the tip of the cooling protection tube to remove any dust deposits. The patented CEMTEC swivel drive prevents deformation of the cooling protection tube from falling debris and the cementing of the gas sampling probe by continuously turning within the combustion chamber.

System configuration

- CEMTEC gas extraction probe

- Local Control Panel

- PLC control cabinet

- Heat exchanger cabinet

- Compressed air tank

- COMTEC O2 / COeInSituanalyser system (optional)

- Extractive analyzer for measurement of SO2, NOx, CO2, etc. (optional) ENOTEC - Trust in Process